Implementation of two Pilots to replace components with negative environmental impact with others that promote intelligent and sustainable growth in the SUDOE area.

Pilot 1: Validation of Cr(VI) substitution process in chromium electrodeposition.

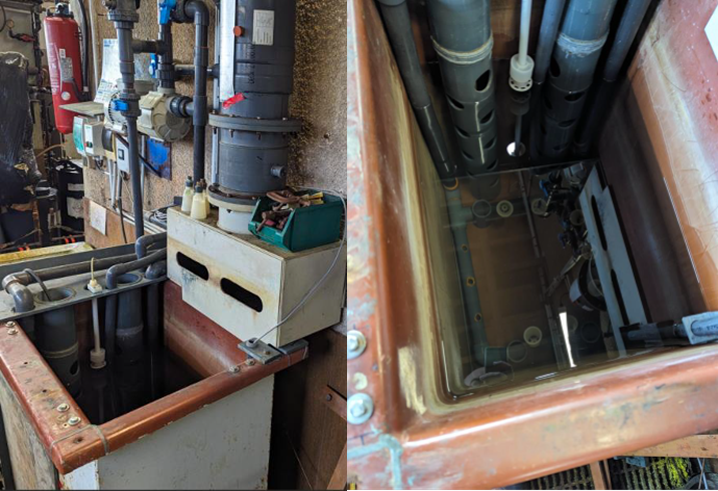

Chromium coatings will be performed with both organic (commercial) and inorganic (in-house formulated) electrolytes. The process will be implemented and validated at Chrome Dur Industriel’s facilities (France), and monitoring systems for the control of working electrolytes will be developed.

Pilot 2: Validation of Cr(VI) substitution process in the protection of light alloys.

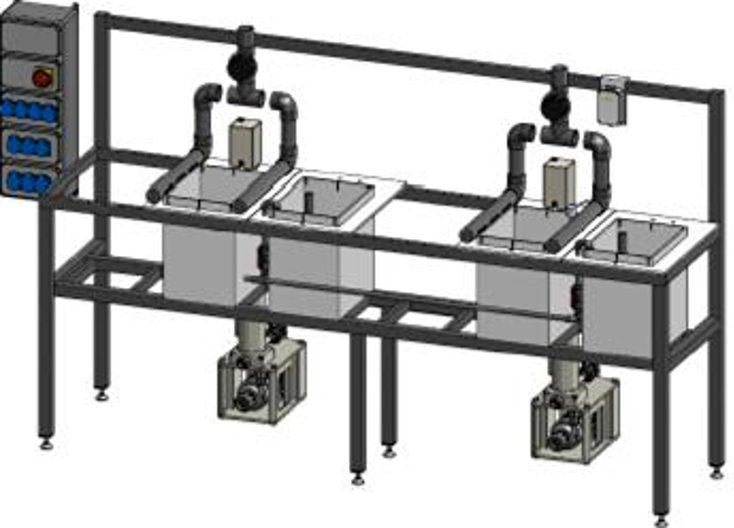

In a first stage, specific anodization and conversion layer pretreatments will be tested, followed by a lacquer-based treatment with corrosion inhibitors incorporated in the lacquer’s formulation. The process will then be implemented and tested in TITANIA’s facilities (Spain). An alternative variant of the process will also be developed and tested in PRIFER (Portugal).