-

Acerca de Nosotros¿Quién gestiona el programa?

-

Convocatorias

-

Noticias y eventos

The RESINSURF project is launching two important pilots to replace environmentally harmful chemicals with safer and more sustainable alternatives in the regions comprising the SUDOE area.

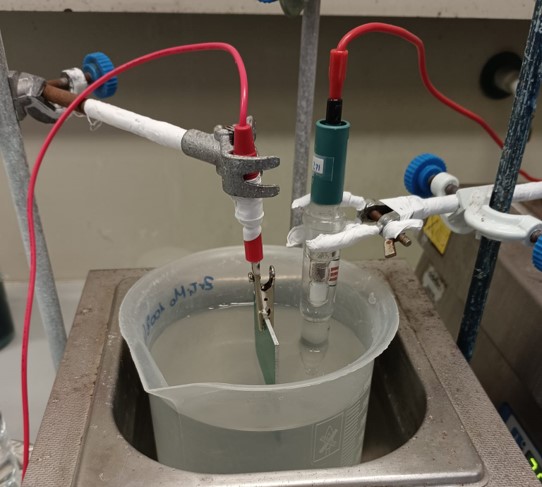

Traditional protection of aluminum alloys uses a multi-layer system that includes chemicals with hexavalent chromium (Cr(VI)), which is toxic. Due to restrictions in Europe, safer alternatives have been found. For example, chromic anodizing has been replaced by methods such as tartaric-sulfuric and boric-sulfuric anodizing, which do not contain Cr(VI). Currently, research is being conducted on the creation of completely chrome-free primers and coatings, using techniques such as sol-gel and organic coatings with inhibitors.

In this Project, two completely chrome-free alternatives will be developed and optimized. The main difference between the two is the generation of the first treatment layer, the one closest to the surface. The following will be tested:

For the anodic layer alternative, the addition of corrosion inhibitors, developed by SMALLMATEK, will also be tested.

In parallel, work will be done on implementing monitoring and control methods for the formulas (or baths) used and the final parts, to have efficient control of the evolution of the baths and guarantee the quality of the treated metal parts.

The following institutions participate in the development and implementation of this pilot:

CIDETEC, SMALLMATEK, and the University of Aveiro.

The validation of Pilot 2 will be carried out at:

TITANIA (see map below)